Worktables, ventilated cold or static cold?

In the world of pastry and viennoiserie, optimal preservation of ingredients and finished products is essential to guarantee quality and freshness. Refrigerated worktables play an important role in this process due to their practicality and specificity, and the choice between a static cold system and a ventilated cold system can have a significant impact on the quality of preservation. However, the requirements for pastries differ from those for viennoiserie because the use of this equipment is not the same. Here is an overview of the advantages and differences between these two types of worktables.

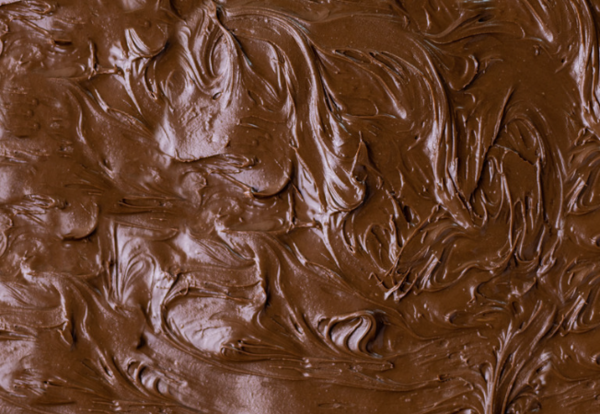

Above all, it is important to choose the right material for the top of the machine. Pastry chefs and chocolatiers prefer a stainless steel top, often with a rounded back for easy cleaning. This material is hygienic and the insulating properties of the stainless steel top mean that the temperature of the chocolate is not affected, and it is resistant to dirt. The tourier, on the other hand, will prefer the more robust granite top, which is often refrigerated so that he can beat his butter without risking melting it when his puff pastry is spread out on his work surface.

Then comes the choice of type of refrigeration.

Static Cold Worktable

The static cold worktable works by allowing cold air to circulate freely inside the cabinet. This system is ideal for finished pastries combining fondant and crispness, toppings or icings, as it allows for optimal preservation without drying out or wetting the products. Humidity is very well managed and the dough stored there does not risk going stale.

Advantages:

- Quiet and Economical: Static cold towers are generally quieter and consume less energy, which can be an advantage for small pastry shops or bakeries.

- Less drying out: this system is particularly suitable for products that are sensitive to dry air, as it does not cause rapid drying out.

Easy maintenance: the absence of a fan reduces maintenance requirements and the risk of mechanical breakdowns.

Disadvantages:

- Temperature to be monitored: The temperature inside the cabinet can vary, which can affect the quality of preservation of sensitive products.

- Sensitivity to Inlets of Hot Air: Frequent opening of doors can lead to inlets of hot air, disrupting the internal temperature and even causing areas of frost.

Ventilated Cold Worktable

The ventilated cold worktable uses a fan to distribute cold air evenly throughout the compartment. This system is particularly suitable for products that require a constant temperature and no frost.

Advantages:

- Uniform Temperature: Ventilated cold ensures a uniform temperature throughout the cabinet, which is ideal for easy product preservation.

- Intensive Use: Ventilated cold is recommended for deep pastry towers and for intensive use, as it allows the cold to be distributed throughout the space and thus stop bacterial growth.

Disadvantages:

- Cost and Energy Consumption: Ventilated cold towers can consume more energy due to the presence of the fan.

- Risk of Drying Out: Products must be covered to avoid drying out due to continuous air circulation.