How do I choose between a proofing cabinet and a proofing chamber?

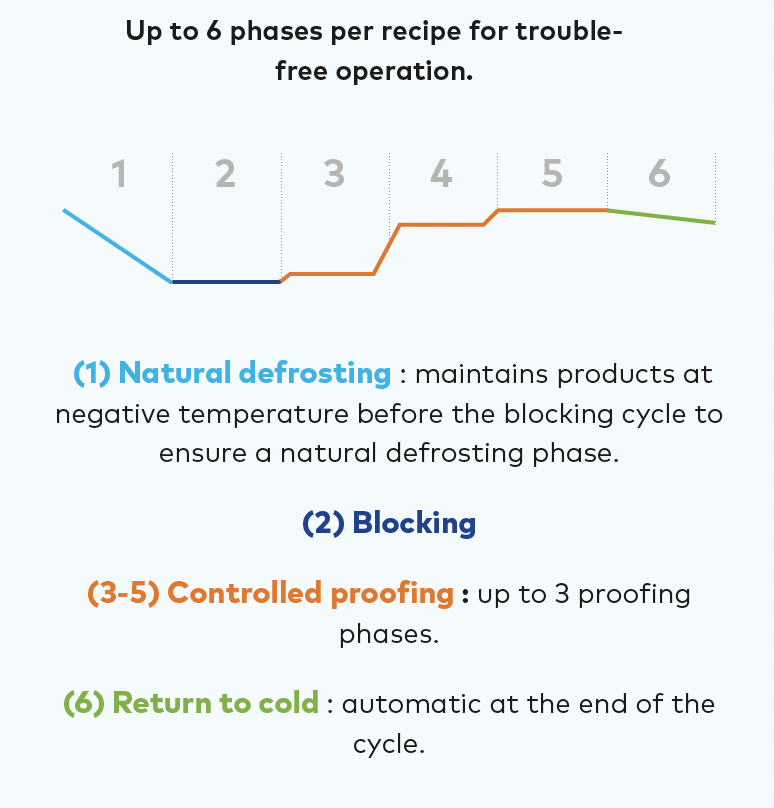

Controlled fermentation equipment is now an essential part of any modern bakery. They are obviously used to precisely manage the doughnut fermentation process, by controlling temperature and humidity conditions, as well as the duration of the various phases of the cycle (often from -10°C to 40°C - 50% to 95% RH).

Controlled fermentation equipment is now an essential part of any modern bakery. They are obviously used to precisely manage the doughnut fermentation process, by controlling temperature and humidity conditions, as well as the duration of the various phases of the cycle (often from -10°C to 40°C - 50% to 95% RH).

In this way, they help to standardize manufacturing processes and achieve consistent results, regardless of external conditions. This helps optimize the quality of finished products, while providing great flexibility in work organization. First and foremost, they enable the decoupling of production stages: with controlled fermentation, it is possible to slow down or temporarily halt fermentation (by lowering the temperature), thus enabling work to be better planned, then restart it by raising the temperature, while adjusting the humidity, which results in a supple dough that increases in volume while developing its aromas. The baker can thus choose to knead his dough one day, then ferment it overnight so as to bake it at the last moment in the morning and have warm bread when he opens his store.

In baking, a proofing cabinet and a proofing chamber are both used to control temperature and humidity conditions to promote the fermentation of your bakery products' dough, but they differ in size, use and design.

Proofing cabinet :

More compact, it can accommodate 400x600 mm or 600x800 mm grids, plates or trays, and a few sizes in between.

- Technical points: consists of a ceiling, 3 sides and a floor that are hermetically sealed, giving it a high degree of insulation, especially from the floor, since it is mounted on feet or castors. It also houses a door with a seal on all 4 sides. It's a high-performance piece of equipment.

- Use: ideal for specific needs or for fermenting moderate quantities of dough.

- Portability: can be moved around the bakery if required. Its door can often be reversed for an opening adapted to all bakeries.

- Example of use: a baker producing small batches of viennoiseries or artisan breads requiring a fairly low capacity with a very specific temperature and humidity cycle.

Proofing chamber:

This is a truly insulated room in which to place carts supporting large quantities of grids, plates or bins. Rooms can often accommodate from 2 to 10 carts of different sizes.

- Technical points: designed for high-volume production, carts often roll over the tiled floor, which means that thermal insulation is lacking at the bottom. However, the careful design of the panel soles and rounded corners ensure easy cleaning, and the solution of a seal at the bottom of the door ensures a very low level of air leakage, and therefore of heat loss.

- Use: optimal for handling large volumes and ensuring homogeneous proofing of many dough pieces at once.

- Fixity: generally fixed, occupying a dedicated room or a large area of the bakery or laboratory.

- Example of use: an industrial bakery or artisan baker with a high demand for daily bread.

In short, the choice between a proofing cabinet and a proofing chamber depends on production volume and the specific needs of the bakery. A proofing cabinet is suitable for small-scale production or product diversification, while a proofing chamber is indispensable for mass production.

Further information

Application

Proofing cabinet :

- Specific production: Often used for proofing specific dough pieces (viennoiseries, special breads) or small quantities.

- Accuracy: Allows precise management of a variety of batches, with programmable cycles to adjust proofing according to the product.

- Versatility: Suitable for both long and short fermentations, depending on requirements.

Proofing chamber :

- Mass production: Ideal for handling large volumes with standardized cycles.

- Loading and unloading: Enables the insertion of several carts loaded with dough pieces, thus optimizing production flow and reducing the number of door openings that disrupt temperature and humidity control.

- Versatility: suitable for both long and short fermentations, as required.

Cleaning

Proofing cabinet :

- Regular cleaning: Requires frequent cleaning of interior surfaces to prevent flour deposits, mold or bacterial growth.

- Seal maintenance: Door seals must be inspected and cleaned regularly to ensure a good seal.

- Moisture management: Care must be taken to keep water tanks clean to avoid lime deposits.

Proofing chamber :

- Extensive cleaning: Requires thorough cleaning, especially of grilles, ventilation systems and interior surfaces.

- Drainage management: Drainage systems must be monitored for blockages.

- Strict hygiene: Given the large size and volume handled, rigorous maintenance is crucial to avoid contamination.

Ergonomics

Proofing cabinet :

- Compact size: Suitable for small spaces, often equipped with castors for easy movement.

- Accessibility: Plates are easy to insert or remove thanks to adjustable shelves.

- Ease of installation: Requires a conventional power supply, sometimes also a water inlet and drain for humidification.

Proofing chamber :

- Accessibility: Stand-up access, with wide doors for easy insertion and removal of carts.

- Customization: Can be configured to suit workshop requirements, with adjustable dimensions.

- User interface: Generally equipped with more complex control systems (tunnel configuration, centralized management).

Maintenance

Proofing cabinet :

- Component monitoring: Regular cleaning of the condenser and regular checking of thermostats, humidity sensors and fans to ensure optimum operation.

- Parts replacement: Parts such as gaskets or resistors can wear out quickly and require replacement.

- Technical interventions: Easier to manage because the cabinet is an independent, compact piece of equipment.

Proofing chamber :

- Preventive maintenance: Periodic checks of control systems, condensers, evaporators and sensors.

- Steam system checks: Particular attention must be paid to the steam generator to avoid scale deposits or corrosion.

- Specialized intervention: Being more complex, chambers often require the intervention of qualified technicians in the event of a breakdown.

In short, flexibility of use, ergonomics and maintenance are simpler with a cabinet, while a chamber offers greater capacities at the price of increased maintenance and servicing constraints. The choice depends on production requirements and the resources available for maintenance.